dev.a

Details and features

Chemistry

Our machine supports all still photography development processes, we cover both black and white and color and both negatives and positives.

You will have 6 different chemistry tanks at your disposal that you can fill with 6 different chemicals, even the most demanding processes are supported. If you’ve always been using a 6-baths E6 kit to develop your precious slides, don’t worry, our machine is here to help.

When the process is done you can recover the chemistry using the taps on the front of the machine, alternatively, in case of one-shot chemistry, everything can be automatically discarded directly after processing.

Water used in washing steps can come from spare chemistry tanks or from the water bath used for temperature control.

In processes where they’re needed, stabilizers and wetting agent steps, should be performed manually outside the machine to avoid excessive foaming and bubbling.

We teamed up with the italian photochemsitry manufacturer Bellini Foto to validate and improve our development results, check out the details in the dedicated page!

Temperature control

Precise and effective temperature control is extremely important in color processes such as C41 and E6 or, more in general, is necessary to obtain consistent and reproducible results.

The chemistry tanks and the film tank can be fully immersed in a recirculating water bath that heats everything up to the desired temperature and, once the temperature is reached, maintains it consistently throughout the process.

The water bath can be filled and managed in two ways:

- automatically: if the machine is connected to a pressurized water source, such as a sink faucet

- manually: by pouring the water into the bath from a bucket or a jug

And when you’re done processing, the water serves a second purpose and will not be wasted, it can be used in the automatic cleaning process.

Film Tanks

Our film tank comes in three different sizes to support your processing needs as efficiently as possible. With our machine you can process all commonly available formats, from 35mm rolls up to 8×10 sheets.

For 35mm or 120 rolls, our tanks are compatible with Jobo series 1500 reels or with Paterson/AP reels.

For large formats we provide our own custom reels, their capacity is listed in the table along with those for Jobo and Paterson reels. Large format reels have a plastice center core and a stainless steel film holder part coated with an epoxy paint to prevent scratching the film while loading and unloading it.

Film rotation is provided by a motor and two gears, one is connected to the motor and the other is connected to the tank column, when the motor spins the film loaded into the tank spins as well. Leakproof seals on both ends are provided by two shaft seals.

Rotation parameters, such as speed and inversion interval, can be configured via software.

We have a lineup of three different tank sizes to suit your processing needs. The following table lists film capacity and required chemistry for each tank (different film types combinations in the same tank are also possible).

| Tank size | Required chemistry |

35mm | 120 | 4×5 | 5×7 | 8×10 |

|---|---|---|---|---|---|---|

| Small | 500ml | 2 | 1-2 * | – | – | – |

| Medium | 700ml | 4 | 2-4 * | 2 | 1 | – |

| Large | 1L | 6 | 3-6 * | 4 | – | 1 |

* The double 120 capacity refers to Jobo 1500 reels, with them it’s possible to load two 120 rolls on the same reel without the risk of overlaps using the red tab.

User interface

The machine is controlled using the large 7″ touch display and an intuitive user interface. Forget about seven-segment displays, bulky knobs and buttons, using dev.a will be just as easy as using an app on your phone.

The machine comes with a few presets but everything is customizable, even if some processes are standard we believe that you must be able to tweak the settings to follow the instructions supplied with the chemistry that you’re using. This machine must be a versatile tool, not a restriction.

Up to 100 custom processes with up to 30 steps each can be stored on the machine, entering process data will be extremely easy using the on-screen virtual keyboard.

If you need complete darkness in your darkroom the display and the status led can be turned completely off without shutting the machine down. This way you can keep printing or doing other darkroom work even if the machine is processing some film in the background. The display frame is hinged on the top plate and can swivel in and out, this way, when you don’t need to use it, it can rest flat against the machine body and be out of the way.

You can import/export your settings and processes to a USB drive to have a backup of your data or to move everything to another machine without having to enter everything again from scratch.

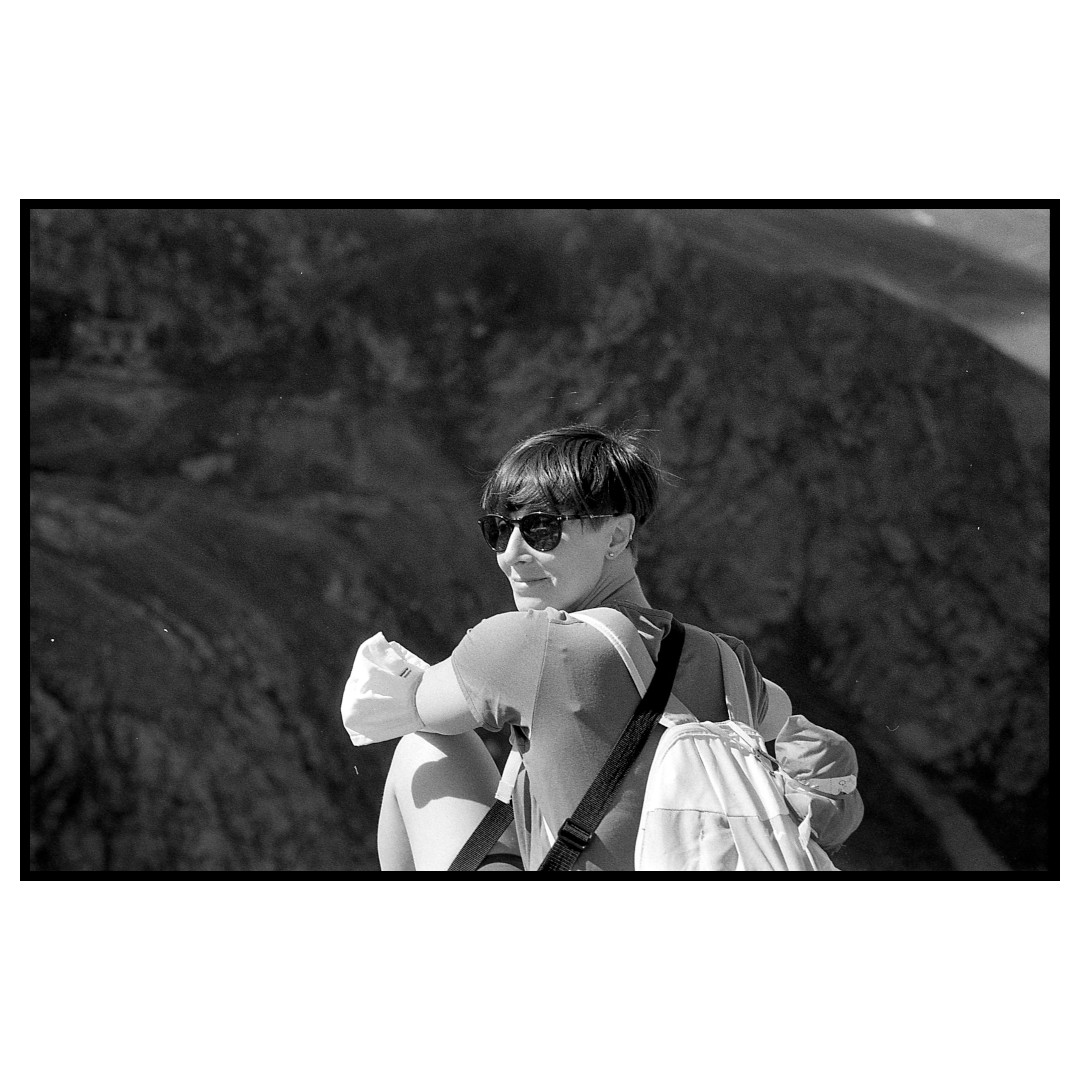

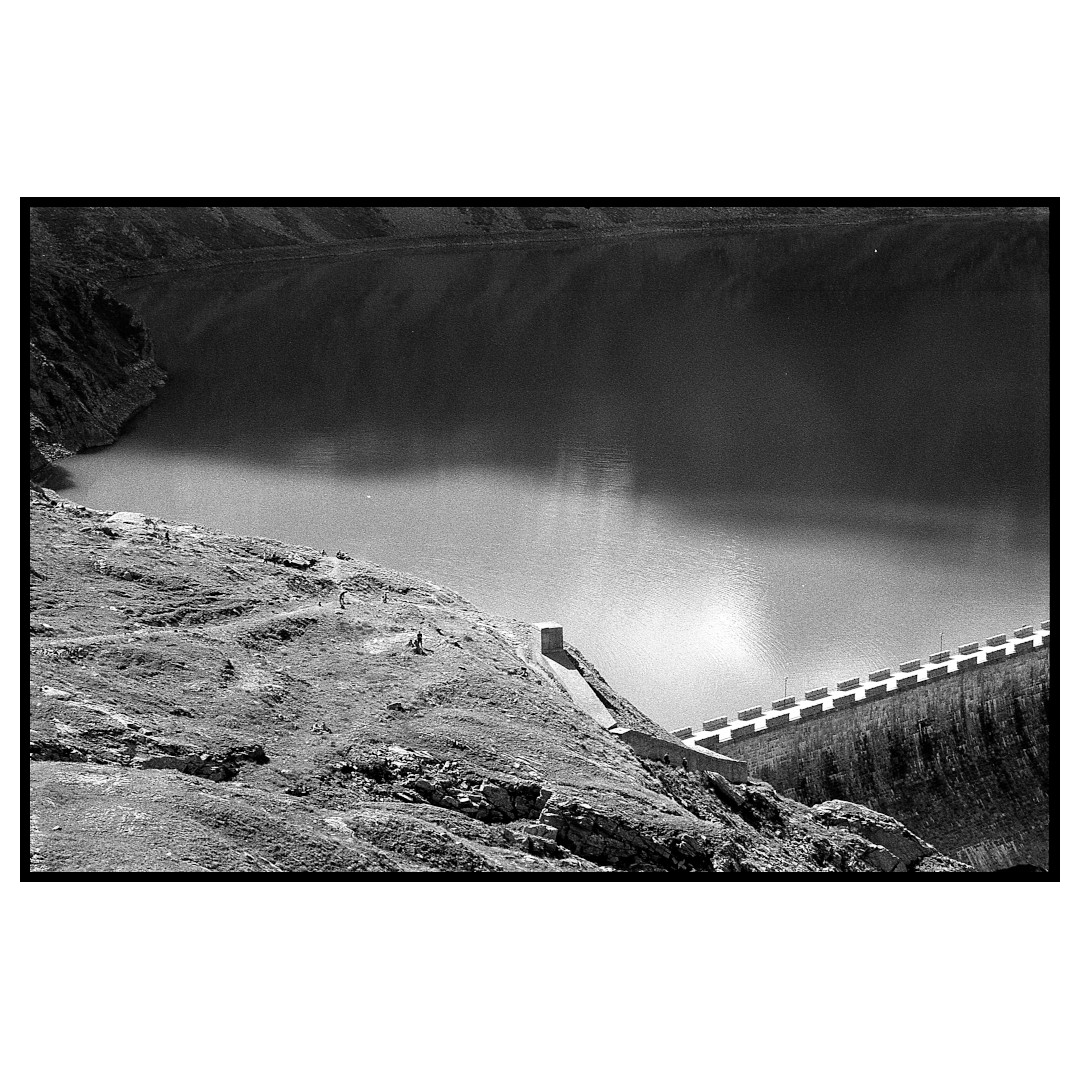

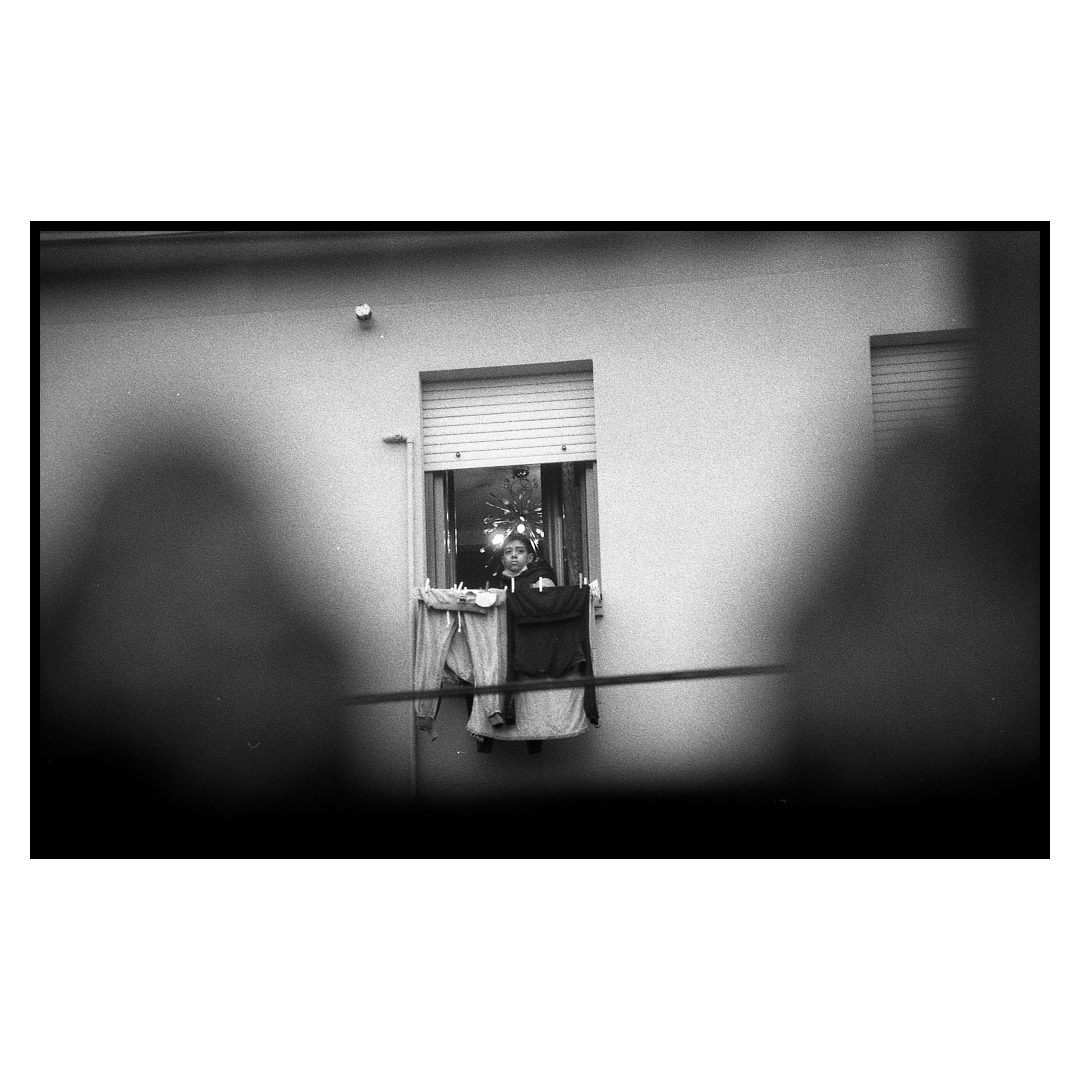

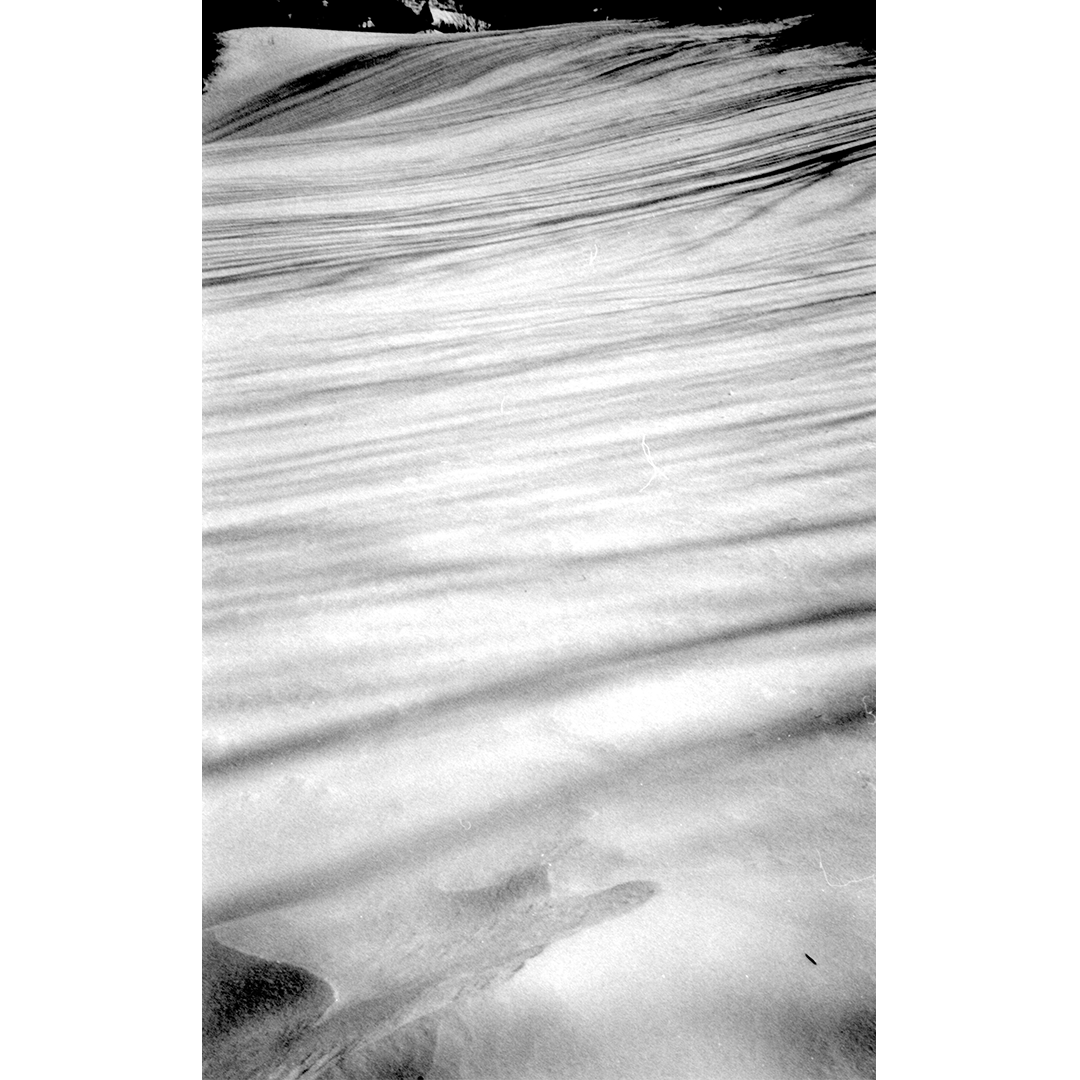

Gallery

Here we have some images developed with our machine: